New method for specimen support manufacturing can help to meet increased global demand in research relying on cryo-EM

The demand for biological structure determination by electron cryo-microscopy (cryo-EM) is growing exponentially, but the supply of specimen support grids cannot cope with this increase. Now, Chris Russo’s group, in the LMB’s Structural Studies Division, describes a new method to make specimen support grids in a scalable way that could help with the huge worldwide demand.

Grids are the ‘fuel’ for electron microscopes – a constant supply is needed to keep the microscopes running for structural biology research. More than one million grids are currently used around the world each year, and this is projected to increase to two or three million per year by 2025. The existing manufacturing methods require each grid to be handled individually by a sharp-sighted person with fine tweezers multiple times; a time-consuming process that is already failing to keep up with demand levels.

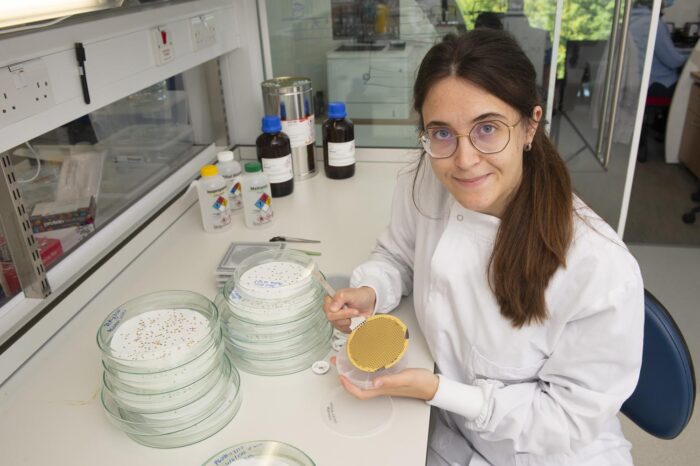

Chris’ group is focused on improving cryo-EM techniques. In 2020, they described a new type of improved all-gold grids called HexAuFoil® which completely eliminate the movement of the specimen during imaging. Since then, many researchers have requested access to the new grids, but the team were unable to meet this demand due to the slow process of making grids one-by-one. To tackle this problem and increase access to the new HexAuFoil® gold grids, Chris and Katerina Naydenova, a PhD student in Chris’ group, took on the challenge of reimagining the grid fabrication process.

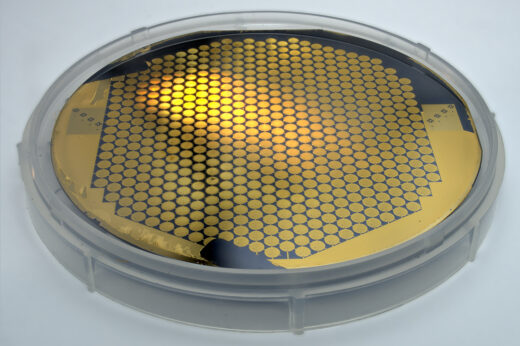

Starting with raw materials and borrowing methods from the semiconductor industry, they developed a new method in which grids are built from the bottom-up. This involves starting from a plain silicon wafer, patterning it with an array of small holes, then covering this with a thin metal foil before outlining each grid (a 3 mm circle) and growing gold grid bars on top by electroplating, before finally releasing the individual grids from the wafer. This method can make 600 grids at a time from a single 4-inch wafer without requiring the handling of the individual devices at any stage of the process. In a commercial setting, a small team will be able to make tens of thousands of grids per day, keeping up with the global demand.

One challenge of the project was to ensure small enough holes were made on each grid. Previous work from Chris’ group showed that the movement of specimens during imaging is stopped completely if the holes are made small enough, so this was a key design parameter for the new manufacturing method. The grids require hole spaces of 300 nm – smaller than the wavelength of visible light – which was achieved using a technique called phase-interference lithography. In addition, the researchers needed to ensure the holes in the gold foil remained round in shape. They managed this by evaporating the gold film while cooling the template with liquid nitrogen in a method they named ‘cryoEvap’.

This ambitious project was a large undertaking, utilising the LMB’s long-standing strengths in method development. The scientists worked closely with LifeArc, the medical research charity who provides technology transfer support to the MRC, to file a patent and a trademark application covering HexAuFoil® and its manufacturing method. The technology was then licensed to Quantifoil Micro Tools GmbH in Jena Germany, which is part of the SPT Life Sciences group headquartered in Melbourn Science Park, Melbourn UK. Now, due to this new large-scale method for making the grids, HexAuFoil® grids will become accessible to everyone in the cryo-EM field. There was collaborative input from the LMB’s electron microscopy facility, scientific computing, mechanical workshop, electronics workshop and estates team.

The work was funded by UKRI MRC, the Wellcome Trust, a Vice-Chancellor’s Award (Cambridge Commonwealth, European and International Trust) and a Sir John Bradfield Scholarship from Trinity College, Cambridge.

Further references

Integrated wafer-scale manufacturing of electron cryo-microscopy specimen supports. Naydenova, K. and Russo, CJ. Ultramicroscopy. Vol 232 (113396).

Chris Russo’s group

Nature – Revolutionary cryo-EM is taking over structural biology

Quantifoil press release

Previous Insight on Research

Freezing molecules completely still for cryo-EM

Golden grids for electron cryo-microscopy